Nd:YLF — Nd-doped Lithium Yttrium Fluoride

Features

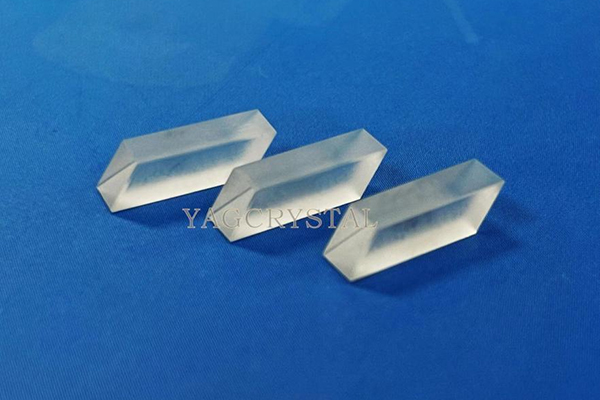

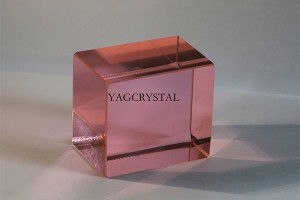

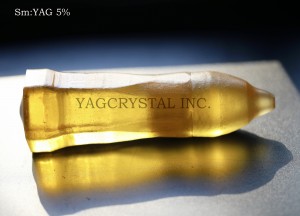

Nd:YLF crystal, also known as Nd-doped lithium yttrium fluoride, is a lithium yttrium fluoride crystal that produces 1047nm and 1053nm lasers. The main advantages of Nd:YLF crystal are: super large fluorescent linewidth, low thermal lens effect, continuous laser application Lower excitation light threshold, natural polarization, etc. Therefore, Nd:YLF crystal, neodymium-doped lithium yttrium fluoride is an ideal laser crystal material for continuous laser and mode-locked laser. The Nd:YLF crystal we provide, Nd-doped lithium yttrium fluoride grown by Czochralsky method, can provide Nd:YLF crystal rod or Nd:YLF crystal plate with different doping concentration.

Features

● Small thermal lens effect

● Wide range of light transmission band

● UV absorption cut-off wavelength is short

● High optical quality

● Output linearly polarized light

| Doping concentration | Nd:~1.0 at% |

| Crystal orientation | [100] or [001], deviation within 5° |

| Wavefront distortion | ≤0.25/25mm @632.8nm |

| Crystal rod size diameter | 3~8mm |

| length | 10~120mm can be customized according to customer requirements |

| Dimensional tolerance diameter | +0.00/-0.05mm |

| length | ±0.5mm |

| Cylindrical processing | Fine grinding or polishing |

| End parallelism | ≤10" |

| Perpendicularity between end face and rod axis | ≤5' |

| Flatness of end face | ≤N10@632.8nm |

| Surface quality | 10-5 (MIL-O-13830B) |

| Chamfering | 0.2+0.05mm |

| AR coating reflectance | <0.25%@1047/1053nm |

| Coating anti-laser damage threshold | ≥500MW/cm |