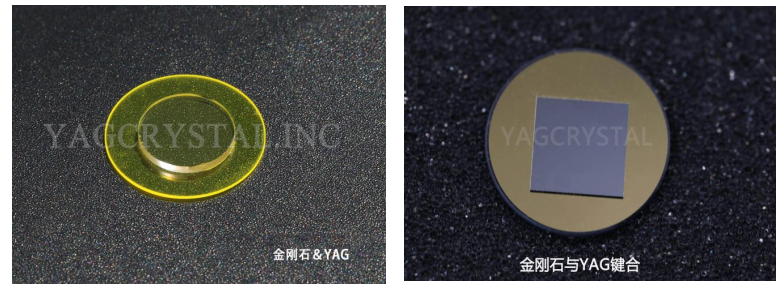

In June 2025, a groundbreaking milestone emerged from the labs of Chengdu Yagcrystal Technology Co., Ltd. as the company announced a pivotal breakthrough in key technologies: the successful bonding of YAG crystals and diamonds. This achievement, years in the making, marks a significant leap forward in laser material science, offering an innovative solution to one of the most persistent challenges in the field—heat dissipation for laser crystals—and holding profound implications for the stable, high-performance operation of lasers across industries.

YAG crystals, long revered as a core material in laser technology, have long faced a critical limitation: during high-power operation, intense energy output leads to rapid heat concentration within the crystal structure. This thermal buildup not only causes gradual performance degradation, such as reduced beam coherence and fluctuating power output, but also shortens the crystal’s service life, directly restricting the precision of laser systems in applications like high-precision cutting, medical laser surgery, and advanced spectroscopy. For decades, engineers and material scientists have sought ways to mitigate this issue, experimenting with various cooling mechanisms, but few solutions have matched the elegance and efficiency of Yagcrystal’s new bonding technique.

At the heart of this breakthrough lies Yagcrystal’s proprietary precision processing technology, which enables the formation of an ultrathin, defect-free interface between YAG crystals and diamonds. Unlike traditional bonding methods that often leave micro gaps or introduce impurities—both of which hinder heat transfer—the company’s approach creates a seamless connection, allowing heat to flow unimpeded between the two materials. This is complemented by diamond’s inherent advantage: with a thermal conductivity up to five times that of copper, diamonds act as nature’s most efficient heat sinks, rapidly conducting and dissipating the excess heat generated by the YAG crystal during operation. Together, the bonded structure forms an integrated, high-performance heat dissipation system that addresses the root cause of thermal degradation.

The impact of this innovation is far-reaching. By effectively avoiding overheating-induced degradation of YAG crystals, the technology significantly improves the stability of laser output, ensuring consistent beam quality even during prolonged high-power use. This reliability is a game-changer for industrial processing, where precise, repeatable laser performance is critical for manufacturing microchips, aerospace components, and other high-tolerance products. In the medical field, it promises to enhance the safety and efficacy of laser procedures, from eye surgery to cancer treatment, by minimizing fluctuations in laser intensity.

Beyond immediate applications, the breakthrough strengthens Yagcrystal’s technical leadership in the laser crystal application field, building on the reputation it showcased at recent exhibitions—where its high-precision optical components and advanced crystals drew widespread acclaim. It also positions the company as a driving force in enabling next-generation laser systems, supporting equipment upgrades in emerging areas like quantum computing, LiDAR for autonomous vehicles, and directed energy technologies.

As word of the achievement spreads through industry circles, it has already sparked interest among laser system manufacturers, research institutions, and end-users eager to integrate the new material into their products. For Yagcrystal, this breakthrough is more than a technical triumph; it is a testament to the company’s commitment to pushing the boundaries of precision optics—a commitment that, as demonstrated both in the lab and on the exhibition floor, continues to redefine what is possible in the world of laser technology.

Post time: Jul-25-2025